Team Update

Last week our local marine biology expert came to talk with the team and since the kids had all prepared their homework, it went well. Everyone got to discuss some of the real-life issues represented in the missions, such as coral degradation and sharks. The team is now narrowing down their innovation project focus, and they have a worksheet to complete for Saturday. The guest speaker also left some useful links to videos for further research.

The talk took a sizable part of our meeting time, but the kids did return to work on solving missions afterwards. Given the relatively little in-garage time before regional competition in November, any work team members can do outside of meeting times will be appreciated. We’ve also decided to make brief videos of individual mission runs when each is completed. These records will be useful not only for keeping account of what we’ve done, but in case we need to revert back to earlier iterations in case parts get switched around.

Class Update

Note that we’re scheduled to host a couple free classes next Saturday, to show folks what we’re doing and to see if some people have interest in the team. I’ve been sending out messages, and hopefully some kids will want to join a team.

Reflection

Learning about mechanical principles is one of the main goals of team meetings, but this learning is in a sense filtered through the LEGO pieces themselves. That is, the principles we explore are limited by what the LEGOs can do. There are certainly limitations. The range of materials is limited to mostly plastic and some rubber, while the scale of the builds doesn’t get much larger than the size of a small cat. Luckily the pieces themselves are capable of a whole lot. Someone actually calculated the entire number of configurations possible using six of the most basic pieces in LEGO, the 2-by-4 studded brick, and the number came out to more than 915 million (that person is Søren Eilers, by the way).

Learning about mechanics this way kind of requires developing an appreciation for and a fluency with individual LEGO pieces, and subsequently building that up into a facility with combining different pieces together. These skills take time to develop. It certainly helps if kids are already comfortable building things with LEGOs, and I think a lot of kids can do this, but one of the initial issues with making stuff on the FLL team is that instead of clicking studded bricks together, kids have to figure out how to use the peg and axle connectors used in LEGO Technic.

This is a peg.

This is a (cross) axle.

They fit in the holes embedded within Technic bricks and beams and form the .

The Technic pieces aren’t exactly intuitive, so one means of getting used to these pieces is simply getting an official Technic set and following set instructions to make the intended model. Assuming that one pays attention to structural durability and other basic physical properties while putting the model together, a builder can gain a sense about what kind of connections function better than others. By building lots of sets, someone can get comfortable making things that work, but this again assumes that the builder maintains an analytical perspective in the process of building to notice why certain configurations are designed as they are. And there isn’t exactly any systematic understanding of mechanical principles and their interrelations to be gained from simply following the set instructions.

Getting used to building with instructions is a good start, but what I think works better is experimenting with the pieces for a functional mechanical goal. This is what I started discussing last week, and it is clear that pure experimentation with Technic pieces has gotten a lot of builders rather far with their creations. This kind of experimentation becomes a kind of exploration of potentialities. The individual LEGO pieces expressly do not have iron-clad rules that determine their functions, so people can use them as they wish, and it’s exciting when someone has a wholly new idea on how something is supposed to work. Experimenting for its own sake produces interesting results, but the nature of such exploration leads to somewhat random results.

Experimenting with a purposive goal in mind has more immediate benefits. For one thing, building to achieve a certain function can instill a sense of the iterative process, that is, a sense that a design can be gradually and continually improved through sustained effort. Iterating is important because a lot of preparation for the FLL competition is about experimenting with mechanisms to see what kind of device can complete a mission consistently and in the shortest amount of time possible. As such, our team has had a lot of group meetings in which we tried to incorporate this experimental, purposive, and iterative method into the plans for our meetings. For instance, we would set a basic mechanical task as a goal, and the kids given a certain amount of time to build something to accomplish the task, either working on their own or in small teams. There’s a low-stakes competition among our group, and then we all go over what worked well and what didn’t.

These simple contests can be really fun and engaging, but there are some issues with using them as the basis for the class. While they were good for introducing mechanical principles, it’s more difficult to get principles to stick, especially as we moved from lesson to lesson. After a few weeks or a summer break without building relevant devices, the kids naturally tend to forget about the principles they used, or at least forget to incorporate them into their subsequent builds. Another issue is that these types of lessons themselves take a good amount of our meeting time. Kids aren’t accustomed to being on the clock when they’re playing with LEGOs, so if they’re limited to an hour to accomplish a task, they invariably ask for ten more minutes whenever the deadline gets close. Time is a big issue for a lot of what the team is doing. These time issues directly translate to preparing for big projects like the FLL competition. Because its challenge missions have a range of mechanical tasks that each require very specific functional mechanisms several degrees removed from the basic, abstract principles of classical mechanics, we can’t spend too much time having everyone perfect individual mechanical principles. The team has to divide up responsibilities, and kids have to specialize, collaborating when they get stuck. So meetings constantly have to balance out general concepts and individual, specific tasks.

What would be useful for the group is a standardized curriculum for building robots out of LEGOs. This doesn’t exactly exist, and it’s what I’ve been working on for the class. LEGO itself has been incorporating more instructional material directly related to the FLL competition into its Spike updates (I briefly describe Spike at this link). For instance, the Spike application/online platform offers instructions for a basic robot that consists of the computerized hub and motorized wheels, but their lessons don’t go over, for instance, how the robot fits into overall competition preparation or the mechanical principles necessary to solve more challenging and complex problems.

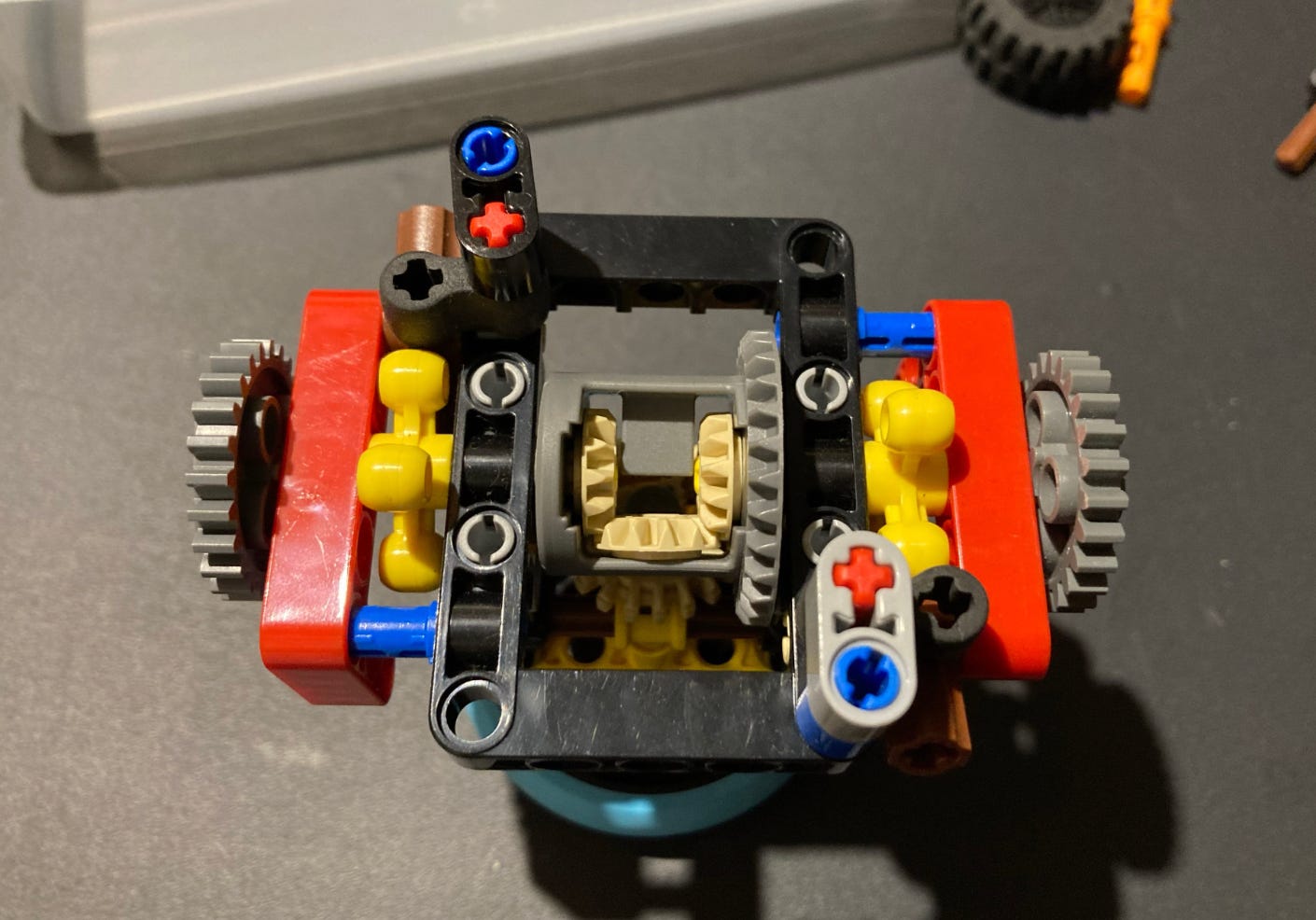

What I’ve been doing is looking at classical mechanics literature, mechanical engineering textbooks (like Shigley's Mechanical Engineering Design), and other materials to see how those lessons are organized. The idea is to adapt those lessons to work with simple LEGO models built around relatively basic pieces, and then move to more complex configurations of LEGO pieces. But this has to start with getting used to making functional, robust machines with basic pegs and axles. Eventually, with enough practice, the kids should all be comfortable using more and more complicated pieces, like the differential gear enclosure below.